Robopac: Reduce costs and protect the environment with ecological stretch wrapping

News General news

Robopac consistently focuses on cost savings with sustainable wrapping technology

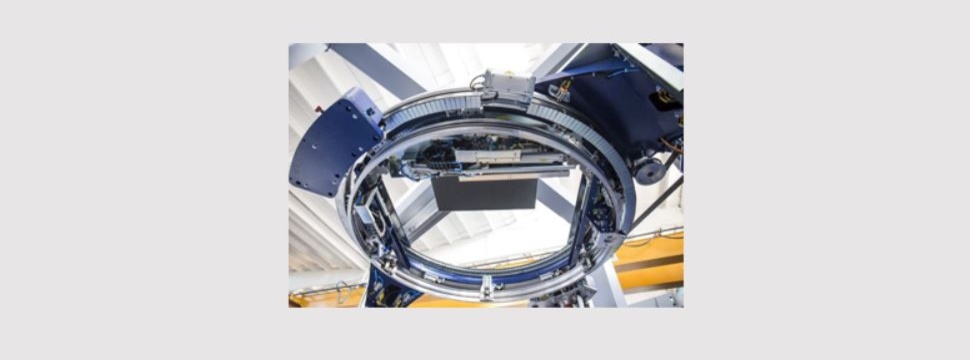

Life cycle assessment, sustainability and environmental friendliness are terms that have now become firmly anchored not only in the minds of end consumers, but also in the minds of more and more companies. However, the consistent implementation of such measures should also have as positive an effect as possible on costs. Robopac Germany, a company of the international Aetnagroup, focuses on intelligent packaging machines for stretch wrapping technologies in the food and beverage industry, which are tested and permanently updated in its own TechLabs. The premium versions include, for example, a new generation of high-performance wrapping machines with patented Cube TechnologyTM, which are suitable for wrapping and stabilizing pallets with stretch film. This guarantees that the right amount of film is always applied at the ideal pallet position and with the maximum amount of force required.

Another positive side effect is that in some cases up to 70 percent of the film material can be saved in this way without sacrificing the highest possible quality. However, not every stretch film is equally suitable for use in these modern packaging machines. The film material must, for example, run at high wrapping speeds and have strong flexibility and load stability, such as films from manupackaging. Converted to the daily goods throughput of an average brewery of 1,400 pallets, around 280 kg less plastic can be used here. Multiplied by an annual production, the savings amount to up to 70,000 kilograms of plastic or the equivalent of 140,000 euros.

On the cost side, companies can expect some massive changes in the near future. Since Jan. 1, 2021, the federal government still pays 80 cents to the EU for every unrecycled kilogram of plastic. However, there are plans to distribute these not inconsiderable expenses among companies in the future. In plain language, this means a correspondingly high financial burden for companies with high plastic consumption. Prices of up to 2 euros per kilogram are currently being discussed. On the other hand, companies that consistently recycle or already use intelligent wrapping technology in their packaging will have a permanent advantage.