Trend-setting: ReFuels based on waste

News General news

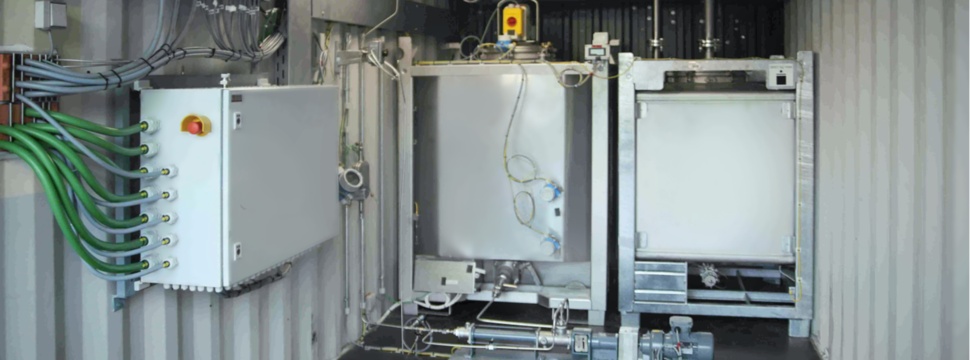

Stainless steel IBCs enable the implementation of decentralised solutions

NEXXOIL, a spin-off of the Hamburg University of Applied Sciences (HAW), has set itself the task of commercialising a patented technology for the production of liquid hydrocarbon fuels from organic waste on an industrial scale. The foundations for the next generation of waste-to-liquid products were researched at HAW Hamburg. Unlike electrofuels (e-fuels), which are produced using large amounts of energy, ReFuels (regeneratively produced fuels) can be produced using energy from organic waste. The process is carbon-neutral and uses stainless steel IBCs from SCHÄFER Container Systems at the beginning and end of the process chain.

In 2008, the Faculty of Life Sciences at HAW Hamburg achieved a technological breakthrough in the chemical core process. Subsequently, over a period of 15 years, the technology was developed from experimental batch operation into a continuous, self-sustaining process for industrial use. It's being commercialised by NEXXOIL.

Closed raw-material cycle with waste-free refineries

An intermediate product obtained from raw materials (biomass, waste oils, food oils andwaste machine oils) is heated and kept at a predefined temperature in the so-called"feedstock container". The container is a SCHÄFER RCB heating container with a volume of1,000litres and an agitator. The centrally arranged agitator serves to distribute the heatevenly in the IBC.

The RCB 1000 has a significantly increased heating capacity of 3.5 kW. This increases the heating speed.

As soon as the necessary temperature is reached in the heating container, the heated intermediate products are fed into the reactor for chemical material conversion via a pump with interposed auxiliary heating. If there is unwanted overpressure in the reactor, another stainless steel IBC acts as a so-called "blow-down container" in order to guarantee safety. The newly obtained fuels are made available for use in another IBC, the "product container".

Stainless steel as a guarantee of safety and durability

Only IBCs with hazardous goods approval are used as "blow-down containers" and as "product containers". A BTA tank container with a capacity of 1,000 litres from SCHÄFER Container Systems is used in each case. The IBC for so-called medium-boiling components or middle distillates is stackable and is approved for metallic intermediate bulk containers according to the ADR, RID, IMDG Code and UN.

Why use stainless steel IBCs? These have increased robustness and first-class stability. Theoretically, the service life of stainless steel IBCs is unlimited. In actual fact, they are often used for many decades. At the end of their lifecycle, stainless steel IBCs have excellent recyclability. A high percentage can be completely recycled as often as desired without the material losing its excellent properties. In other words, "metal recycles forever!"

Economical and decentralised at the place of action

The READi process can be used economically on a decentralised basis on a small scale, from around 2500 tonnes/year. The systems can be operated safely on site, exactly where corresponding waste is produced. The target customers are medium-sized waste disposal companies and manufacturing companies that can use the systems to recycle their wasteflows in an environmentally friendly and economically viable manner.

The focus of the project partners is to contribute to climate-neutral mobility as part of the energy revolution.