Glass industry: Rising energy costs jeopardize energy transition

News General news

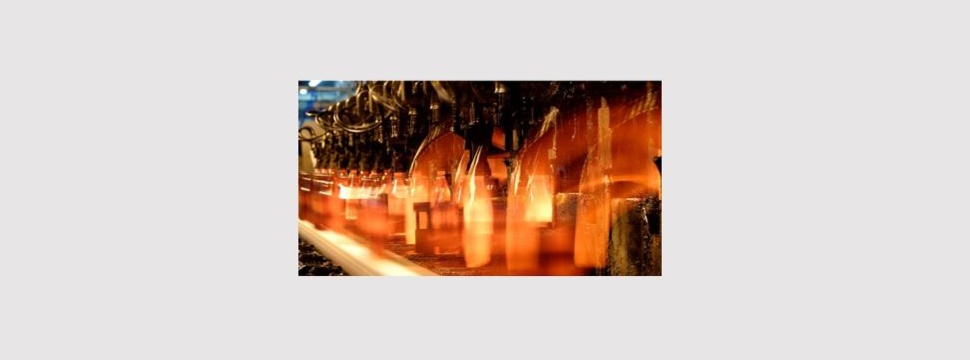

Rising energy costs for electricity and natural gas are also a major concern for the glass industry. As an energy-intensive industry, it faces the challenge of making its processes climate-neutral in the future if it wants to achieve the ambitious political climate targets by 2045. Electricity plays a crucial role in all future technologies - be it the electrification of glass tanks or the switch from natural gas to green hydrogen.

By consistently implementing energy-saving measures, the glass industry has already reduced energy consumption and thus CO2 emissions in recent decades in line with the available state of the art. A further reduction can only be achieved by switching from conventional energy sources - especially natural gas - to alternative, renewable energy sources.

Currently, the focus is on three technologies to decarbonize the glass industry: complete electrification with green electricity, the construction of hybrid glass furnaces that run on electricity and natural gas or, later, hydrogen, and the use of renewable gases, such as hydrogen or biogenic gases. In this context, green electricity is the decisive energy carrier for all technologies; in the production of hydrogen, for example, it is needed for electrolysis.

BV-Glas President Dr. Frank Heinricht says: "The glass industry is facing up to the challenges of the future and is conducting intensive research into the conversion of its processes. However, it is also dependent on politicians creating the necessary infrastructure and framework conditions for the change. Above all, this includes low energy prices in order to remain competitive even after the switch to renewable energy sources.