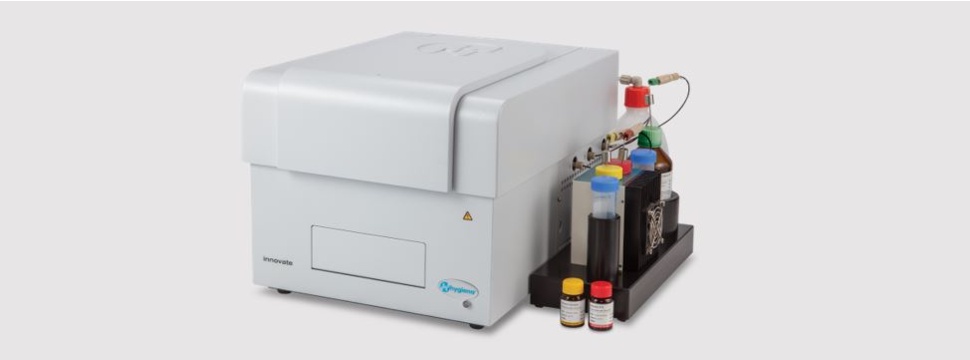

HygienaTM️ Launches New Innovate RapiScreenTM️ Beverage Kit for Ultra-rapid Detection of Microbial Contamination

News General news

The user-friendly, rapid, microbial screening system provides high-performance testing for low pH beverages and quality control results within 30 minutes

Hygiena is pleased to announce a new, ultra-rapid, microbial screening kit that provides high-performance testing for low pH beverages, using the Innovate System. The RapiScreen Beverage Kit provides quality control results in less than 30 minutes following a preliminary incubation period, allowing manufacturers to confirm product quality for quick release to market. This new system reduces product hold time from 4-10 days to 1-2 days, drastically improving inventory turn and cash flow. Additionally, it is specifically designed to have strong buffering capacity to neutralize often complex, high-acid content found in fruit juices. The kit has also been validated on a broad range of matrices beyond fruit juices, including UHT pasteurized products, teas, energy drinks, smoothie mixes and condiments.

When it comes to rapid results, the Innovate System can detect microbial contamination much faster than traditional culture methods. After a 24 to 48-hour incubation, results can be obtained in less than 30 minutes – and for 1 to 96 samples at a time. The system uses a simple three-step process which makes test set-up easy and reduces technician hands-on time. It also features RapiScreen ATP bioluminescence technology, the industry standard for screening dairy and beverage products due to its speed and clear absence / presence results. ATP testing eliminates the need for 4-10-day plate incubation, drastically shortening production times.

Hygiena continually invests in matrix-specific validation studies, optimized buffering capacity and rapid analytical capabilities, to allow food and beverage manufacturers to keep operating at peak performance. The RapiScreen Kits have been validated on raw materials, in-process formulations, and finished goods within the dairy, food, and beverage industries. While the Innovate platform was traditionally used to test dairy and dairy-alternative products, it now also extends out to beverage products such as highly acidic fruit juices.

“With the ever-expanding beverage industry, there is a growing need for rapid quality management and early preventative controls to reduce the risk of product contamination. Thanks to the automation of the system with a high throughput, multiple products can be run on a single microtiter plate every half hour. Subsequent assays can be prepared even while the system is in use to keep high-volume operations running smoothly. By shortening time to results, facilities can reduce inventory requirements, warehouse space and safety stock, resulting in significant savings, which impacts the bottom line positively,” commented Steven Nason, CEO of Hygiena.

“As a global vendor to the largest and smallest food and beverage companies around the world, we have been developing and introducing instruments, kits, and software to the market for more than 20 years to help protect customer brands and products as well as consumers from microbial contamination. RapiScreen is a great addition to our large portfolio of food and beverage diagnostic solutions and further strengthens our mission of helping prevent illness, save lives, and contribute to making the world a safer place,” Steven Nason concluded.

The Hygiena Innovate RapiScreen Beverage Kit Features and Benefits:

- Delivers industry-leading, cross matrix accuracy on low pH beverages

- Reduces product release by 2-5 days, thus reducing inventory and space requirements, as well as safety stock volumes

- Simplifies operation in a streamlined 3-step procedure, shortening hands-on time compared to traditional methods

- Additional buffering capacity neutralizes difficult, acidic products consistently

- Validated on a broad range of matrices

- Based on core technology that has been used in the food and beverage industry for microbial contamination for over 20 years